Innovative Solutions: How Buried Scraper Conveyors Transform Coal Ash Transport

Jul 14,2025

Innovative Solutions: How Buried Scraper Conveyors Transform Coal Ash Transport

In the realm of industrial equipment, the need for efficient and environmentally-friendly transport solutions has never been greater. Coal ash, a byproduct of coal combustion, presents unique challenges in transportation and disposal. **Buried scraper conveyors**, a revolutionary design in the field of material handling, are transforming the way industries manage coal ash. This article delves into the intricacies of buried scraper conveyors, their innovative features, and how they significantly enhance coal ash transport operations.

Table of Contents

- Introduction to Buried Scraper Conveyors

- Understanding Coal Ash: Composition and Challenges

- The Need for Innovative Transport Solutions in Coal Ash Management

- What are Buried Scraper Conveyors?

- Advantages of Buried Scraper Conveyors for Coal Ash Transport

- Applications of Buried Scraper Conveyors in Various Industries

- Environmental Impact and Sustainability of Coal Ash Transport

- Frequently Asked Questions

- Conclusion: The Future of Coal Ash Transport

Introduction to Buried Scraper Conveyors

The transport of coal ash has traditionally relied on methods that often lead to inefficiencies and environmental concerns. **Buried scraper conveyors** present a solution that mitigates these issues by providing a seamless, enclosed system for transporting materials. These conveyors are designed to operate beneath the surface, allowing for unobstructed operations above ground while ensuring that the materials are transported efficiently.

Understanding Coal Ash: Composition and Challenges

Coal ash consists of fine particles that remain after the combustion of coal in power plants. It comprises several components, including fly ash, bottom ash, boiler slag, and synthetic gypsum. Each component has unique characteristics and poses different challenges in handling and disposal.

The main challenges associated with coal ash transport include:

- Dust Control: The fine particles can create dust, leading to air pollution and health hazards.

- Storage Space: Coal ash requires significant storage space, increasing operational costs.

- Transportation Efficiency: Traditional conveyance methods can be slow and cumbersome, resulting in bottlenecks in the workflow.

The Need for Innovative Transport Solutions in Coal Ash Management

As regulations surrounding coal ash disposal become stricter, the demand for innovative transport solutions is pressing. Industries must adopt practices that not only comply with environmental standards but also improve operational efficiency. This is where buried scraper conveyors emerge as a powerful ally in the quest for enhanced coal ash management.

What are Buried Scraper Conveyors?

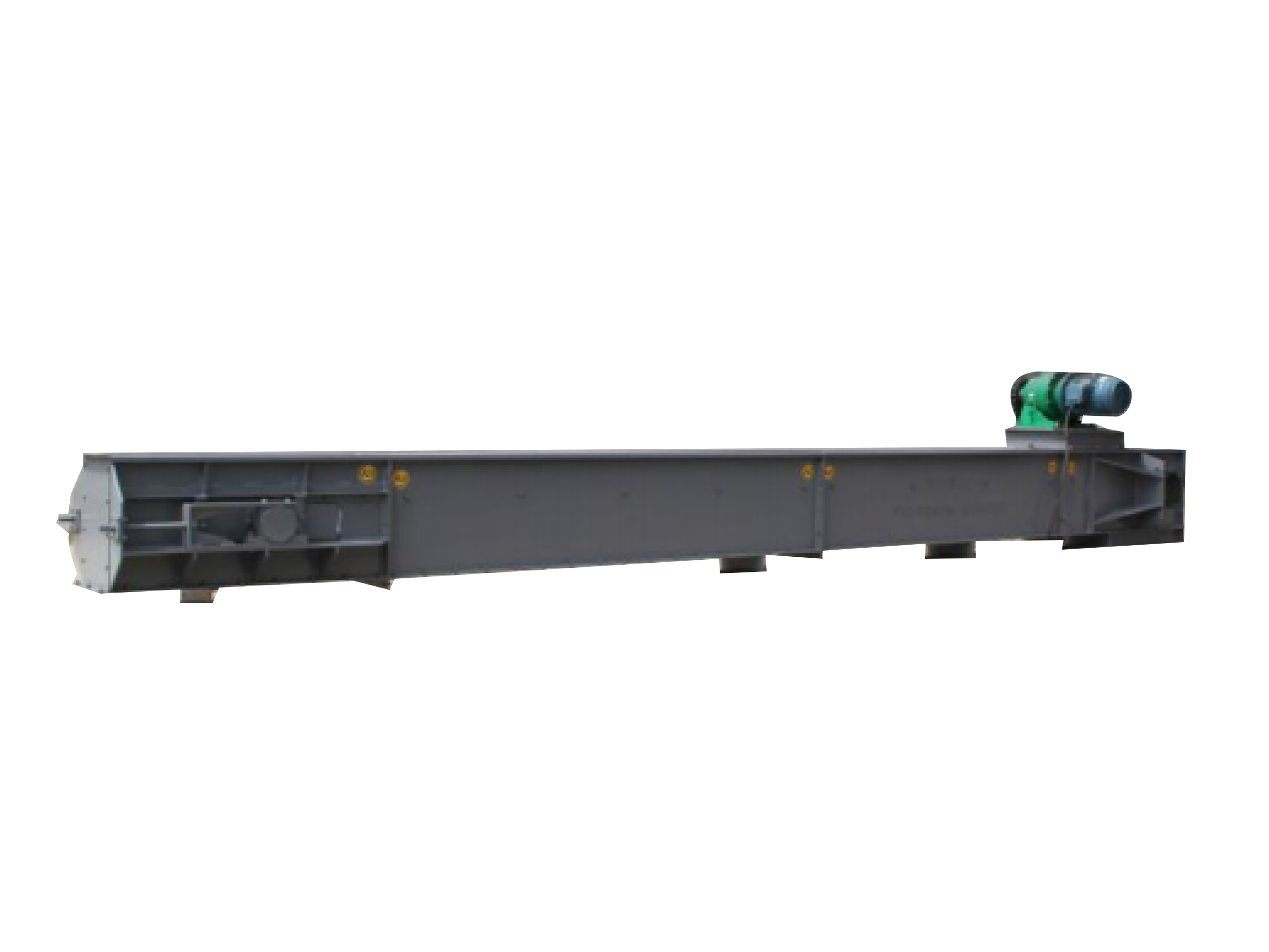

Buried scraper conveyors are specialized systems designed for the effective transport of bulk materials, particularly coal ash. These conveyors operate beneath the ground level, utilizing a series of scrapers attached to a moving belt system to transport materials from one location to another.

Key features of buried scraper conveyors include:

- Enclosed Design: The enclosed nature of these conveyors minimizes dust emissions and environmental contamination.

- Space Efficiency: Operating below ground frees up valuable surface space for other operations or environmental restoration.

- Adaptability: These systems can be customized to fit various layouts and operational requirements, making them versatile for different industries.

Advantages of Buried Scraper Conveyors for Coal Ash Transport

The implementation of buried scraper conveyors for coal ash transport offers numerous advantages:

Enhanced Safety and Reduced Environmental Impact

By keeping the coal ash transport system underground, these conveyors significantly reduce the risk of airborne dust particles. This improvement in air quality is crucial for maintaining the health and safety of workers and nearby communities.

Increased Efficiency and Reduced Operational Costs

Buried scraper conveyors improve material handling efficiency. With their ability to transport large volumes of coal ash continuously and reliably, industries can expect a reduction in operational costs associated with labor, energy, and maintenance.

Integration with Existing Systems

These conveyors can easily integrate with existing infrastructure, allowing companies to enhance their coal ash management processes without the need for extensive overhauls. This flexibility helps companies optimize their operations while minimizing disruptions.

Applications of Buried Scraper Conveyors in Various Industries

While coal ash transport is a primary application, buried scraper conveyors find utility across various industries:

- Power Generation: Essential for transporting coal ash from power plants to disposal sites.

- Cement Manufacturing: Used to handle byproducts and raw materials efficiently.

- Mining: Effective in transporting mined materials and waste products.

Environmental Impact and Sustainability of Coal Ash Transport

One of the critical factors driving the adoption of buried scraper conveyors is their positive impact on environmental sustainability. By minimizing dust emissions and utilizing fewer natural resources compared to traditional methods, these systems align with the global push towards sustainable industrial practices.

Moreover, the enclosed nature of buried scraper conveyors helps in mitigating the potential for coal ash leaching into groundwater, a significant concern for environmental regulators.

Frequently Asked Questions

1. What materials can buried scraper conveyors transport?

Buried scraper conveyors are primarily designed for transporting coal ash, but they can handle various bulk materials, including sand, gravel, and other industrial byproducts.

2. How do buried scraper conveyors improve safety?

The enclosed design reduces dust emissions, thereby enhancing air quality and minimizing health risks for workers and surrounding communities.

3. Are buried scraper conveyors customizable?

Yes, these conveyors can be tailored to meet specific operational requirements, ensuring compatibility with existing systems and layouts.

4. What is the lifespan of a buried scraper conveyor system?

With proper maintenance, buried scraper conveyors can have a long operational lifespan, often exceeding 20 years.

5. How do buried scraper conveyors impact operational costs?

The enhanced efficiency and reduced maintenance needs associated with these systems typically lead to lower operational costs over time.

Conclusion: The Future of Coal Ash Transport

The evolution of coal ash transport through the implementation of **buried scraper conveyors** represents a significant leap forward in industrial efficiency and environmental stewardship. By addressing the inherent challenges associated with traditional transport methods, these conveyors not only streamline operations but also foster a more sustainable approach to managing coal combustion byproducts. As industries continue to seek innovative solutions to their material handling needs, buried scraper conveyors will undoubtedly play a pivotal role in shaping the future of coal ash transport.

Hot Tags:

PREVIOUS:

Contact Us

E-mail:byunfei2000@gmail.com

Wechat/WhatsApp:+86 17324886663

WhatsApp:+86 18738568071

Address:No. 12 Industrial Road, Zhaipo Town, Xinxiang, Henan Province