Understanding Sidewall Belt Conveyors for Incline Transfer: A Comprehensive Guide

Sep 07,2025

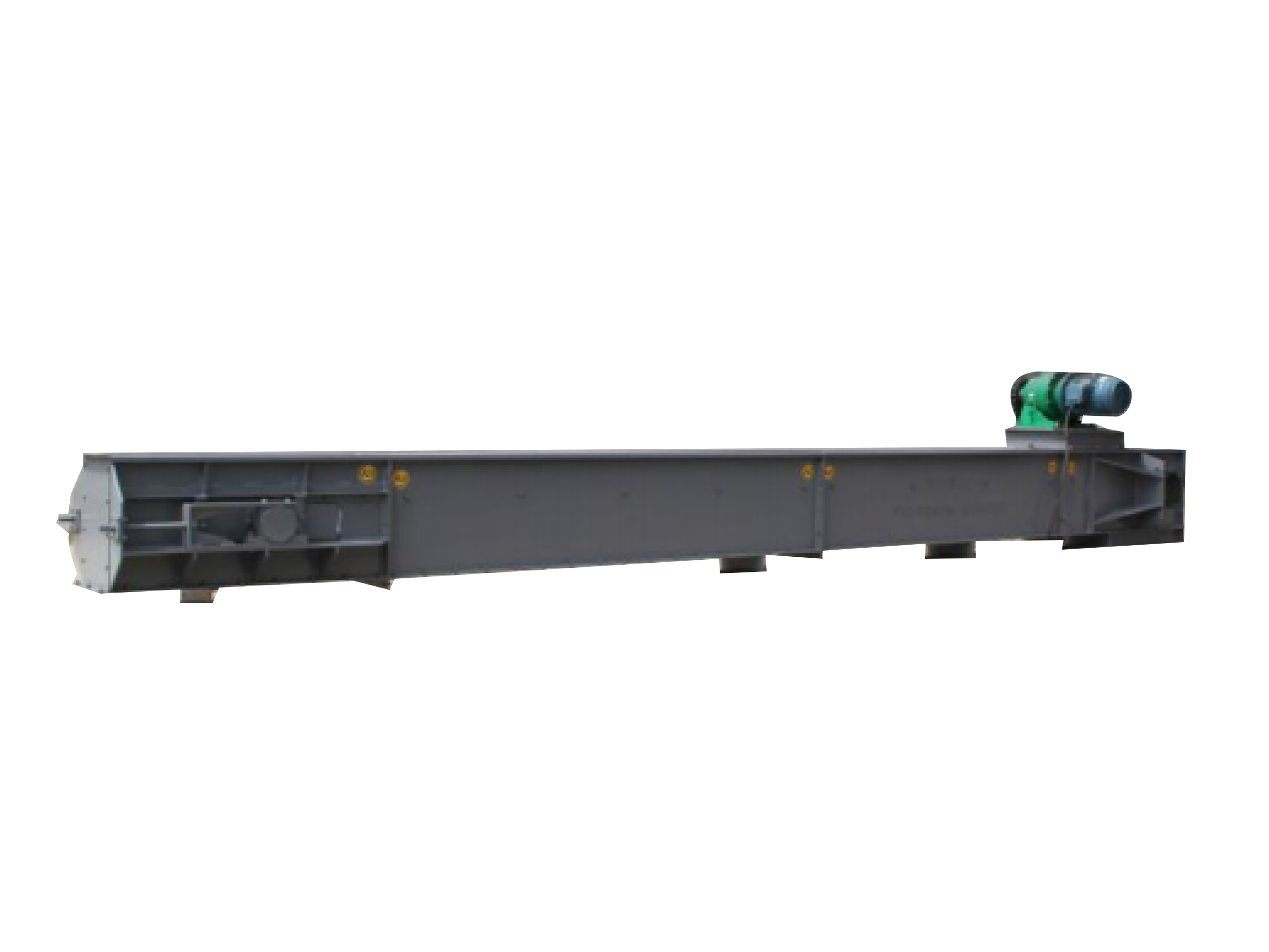

Sidewall belt conveyors are specialized systems designed to efficiently transport materials at an incline, making them an invaluable asset in many industrial settings. Unlike traditional flat belt conveyors, sidewall belt conveyors are equipped with vertical sidewalls that prevent the materials from sliding off during the incline transfer process. This unique design allows for a higher elevation of material transport without compromising the stability of the load.

One of the primary advantages of sidewall belt conveyors is their ability to handle a wide variety of materials, ranging from bulk products like grains and aggregates to packaged goods. The sidewalls help contain the materials, enabling the conveyor to operate at steeper angles—often exceeding 30 degrees— while ensuring that the load remains securely in place. This feature is particularly beneficial in environments where space is limited, and vertical transport is necessary.

In addition to their design, the construction of sidewall belt conveyors typically involves durable materials that can withstand the rigors of daily operations. The belts are often made from high-quality rubber or synthetic materials, providing excellent traction and wear resistance. Furthermore, the sidewalls are usually reinforced to enhance their strength, ensuring they can handle heavy loads without deformation or failure.

Another significant benefit of using sidewall belt conveyors for incline transfer is their versatility in configurations. These systems can be customized to fit specific layout requirements, including varying lengths, widths, and angles of incline. This adaptability makes them suitable for diverse applications, from manufacturing and assembly lines to mining and bulk material handling.

Moreover, sidewall belt conveyors are designed for ease of maintenance and operation. Many models come equipped with features such as adjustable tension systems and removable sidewalls, allowing for quick inspections and repairs. This not only reduces downtime but also extends the lifespan of the equipment, contributing to overall operational efficiency.

In summary, sidewall belt conveyors for incline transfer are a vital component in the industrial material handling landscape. Their unique design, ability to manage various materials, and adaptability to different operational environments make them an excellent choice for businesses seeking to optimize their transport systems. Understanding the functionality and benefits of these conveyors can aid in making informed decisions about material handling solutions, ensuring a more efficient and productive workflow in your operations.

One of the primary advantages of sidewall belt conveyors is their ability to handle a wide variety of materials, ranging from bulk products like grains and aggregates to packaged goods. The sidewalls help contain the materials, enabling the conveyor to operate at steeper angles—often exceeding 30 degrees— while ensuring that the load remains securely in place. This feature is particularly beneficial in environments where space is limited, and vertical transport is necessary.

In addition to their design, the construction of sidewall belt conveyors typically involves durable materials that can withstand the rigors of daily operations. The belts are often made from high-quality rubber or synthetic materials, providing excellent traction and wear resistance. Furthermore, the sidewalls are usually reinforced to enhance their strength, ensuring they can handle heavy loads without deformation or failure.

Another significant benefit of using sidewall belt conveyors for incline transfer is their versatility in configurations. These systems can be customized to fit specific layout requirements, including varying lengths, widths, and angles of incline. This adaptability makes them suitable for diverse applications, from manufacturing and assembly lines to mining and bulk material handling.

Moreover, sidewall belt conveyors are designed for ease of maintenance and operation. Many models come equipped with features such as adjustable tension systems and removable sidewalls, allowing for quick inspections and repairs. This not only reduces downtime but also extends the lifespan of the equipment, contributing to overall operational efficiency.

In summary, sidewall belt conveyors for incline transfer are a vital component in the industrial material handling landscape. Their unique design, ability to manage various materials, and adaptability to different operational environments make them an excellent choice for businesses seeking to optimize their transport systems. Understanding the functionality and benefits of these conveyors can aid in making informed decisions about material handling solutions, ensuring a more efficient and productive workflow in your operations.

Hot Tags:

Contact Us

E-mail:byunfei2000@gmail.com

Wechat/WhatsApp:+86 17324886663

WhatsApp:+86 18738568071

Address:No. 12 Industrial Road, Zhaipo Town, Xinxiang, Henan Province