Innovative Solutions for Incline Transfer: Understanding Sidewall Belt Conveyors

Sep 11,2025

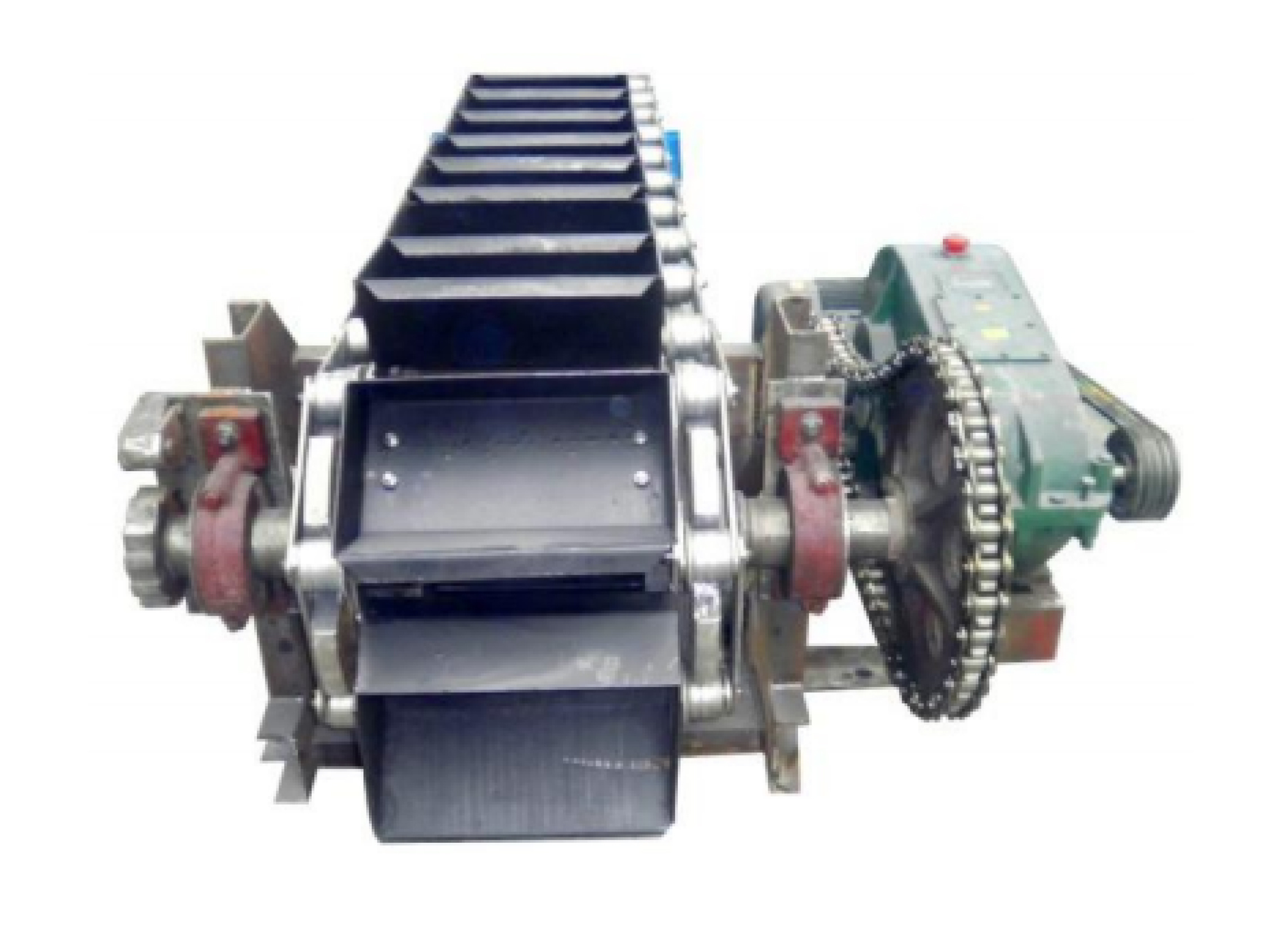

Sidewall belt conveyors are specialized types of conveyors that incorporate vertical sidewalls along the edges of the belt. These sidewalls serve a vital purpose, particularly in incline transfer applications where the movement of bulk materials at steep angles is required. Traditional flat belt conveyors often struggle with the gravity-induced slippage of materials when inclined, which can lead to inefficiencies and increased operational costs. However, the design of sidewall belt conveyors mitigates this issue effectively.

One of the primary advantages of using sidewall belt conveyors for incline transfer is their ability to transport a wide variety of bulk materials, including aggregates, grains, and even packaging items. The sidewalls prevent material spillage, ensuring that the conveyed product remains securely in place. This is especially important in applications where maintaining product integrity and minimizing waste is crucial.

Moreover, the incline design of these conveyors allows for space-saving solutions within production facilities. Instead of spreading out equipment horizontally, businesses can maximize vertical space, ultimately enhancing facility layout and workflow efficiency. This is particularly beneficial in industries where floor space is at a premium.

The construction of sidewall belt conveyors typically involves the use of high-quality materials that can withstand the rigors of industrial environments. The belts are often made from durable fabrics and reinforced with rubber or other robust materials to ensure longevity. Additionally, the choice of sidewall height and design can be tailored to accommodate specific material types and transport needs, providing a customizable solution for various industrial applications.

Maintenance is another critical consideration with sidewall belt conveyors. Regular inspections and timely maintenance can significantly extend the lifespan of the conveyor system and enhance its performance. Key components such as the belt, sidewalls, and drive mechanisms should be assessed periodically to ensure they are functioning optimally.

In conclusion, sidewall belt conveyors represent a versatile and effective solution for incline transfer in industrial settings. Their design not only addresses the challenges associated with material movement at angles but also supports operational efficiency and maximizes space utilization. By understanding the technical nuances and advantages of these conveyors, professionals can make informed decisions that align with their operational goals and enhance productivity in their facilities.

One of the primary advantages of using sidewall belt conveyors for incline transfer is their ability to transport a wide variety of bulk materials, including aggregates, grains, and even packaging items. The sidewalls prevent material spillage, ensuring that the conveyed product remains securely in place. This is especially important in applications where maintaining product integrity and minimizing waste is crucial.

Moreover, the incline design of these conveyors allows for space-saving solutions within production facilities. Instead of spreading out equipment horizontally, businesses can maximize vertical space, ultimately enhancing facility layout and workflow efficiency. This is particularly beneficial in industries where floor space is at a premium.

The construction of sidewall belt conveyors typically involves the use of high-quality materials that can withstand the rigors of industrial environments. The belts are often made from durable fabrics and reinforced with rubber or other robust materials to ensure longevity. Additionally, the choice of sidewall height and design can be tailored to accommodate specific material types and transport needs, providing a customizable solution for various industrial applications.

Maintenance is another critical consideration with sidewall belt conveyors. Regular inspections and timely maintenance can significantly extend the lifespan of the conveyor system and enhance its performance. Key components such as the belt, sidewalls, and drive mechanisms should be assessed periodically to ensure they are functioning optimally.

In conclusion, sidewall belt conveyors represent a versatile and effective solution for incline transfer in industrial settings. Their design not only addresses the challenges associated with material movement at angles but also supports operational efficiency and maximizes space utilization. By understanding the technical nuances and advantages of these conveyors, professionals can make informed decisions that align with their operational goals and enhance productivity in their facilities.

Hot Tags:

Contact Us

E-mail:byunfei2000@gmail.com

Wechat/WhatsApp:+86 17324886663

WhatsApp:+86 18738568071

Address:No. 12 Industrial Road, Zhaipo Town, Xinxiang, Henan Province