Hammer Crushers: The Backbone of Modern Coal Crushing Operations

Oct 07,2025

Introduction to Hammer Crushers in Coal Crushing

In the realm of coal processing, **hammer crushers** serve as indispensable machinery. These robust machines efficiently break down coal into smaller, manageable sizes, facilitating subsequent processing steps. As energy demands increase, the need for efficient coal crushing operations becomes even more pronounced. This article explores the mechanics, advantages, maintenance, and future trends of hammer crushers, providing a thorough understanding of their integral role in modern coal crushing.

Understanding Hammer Crushers

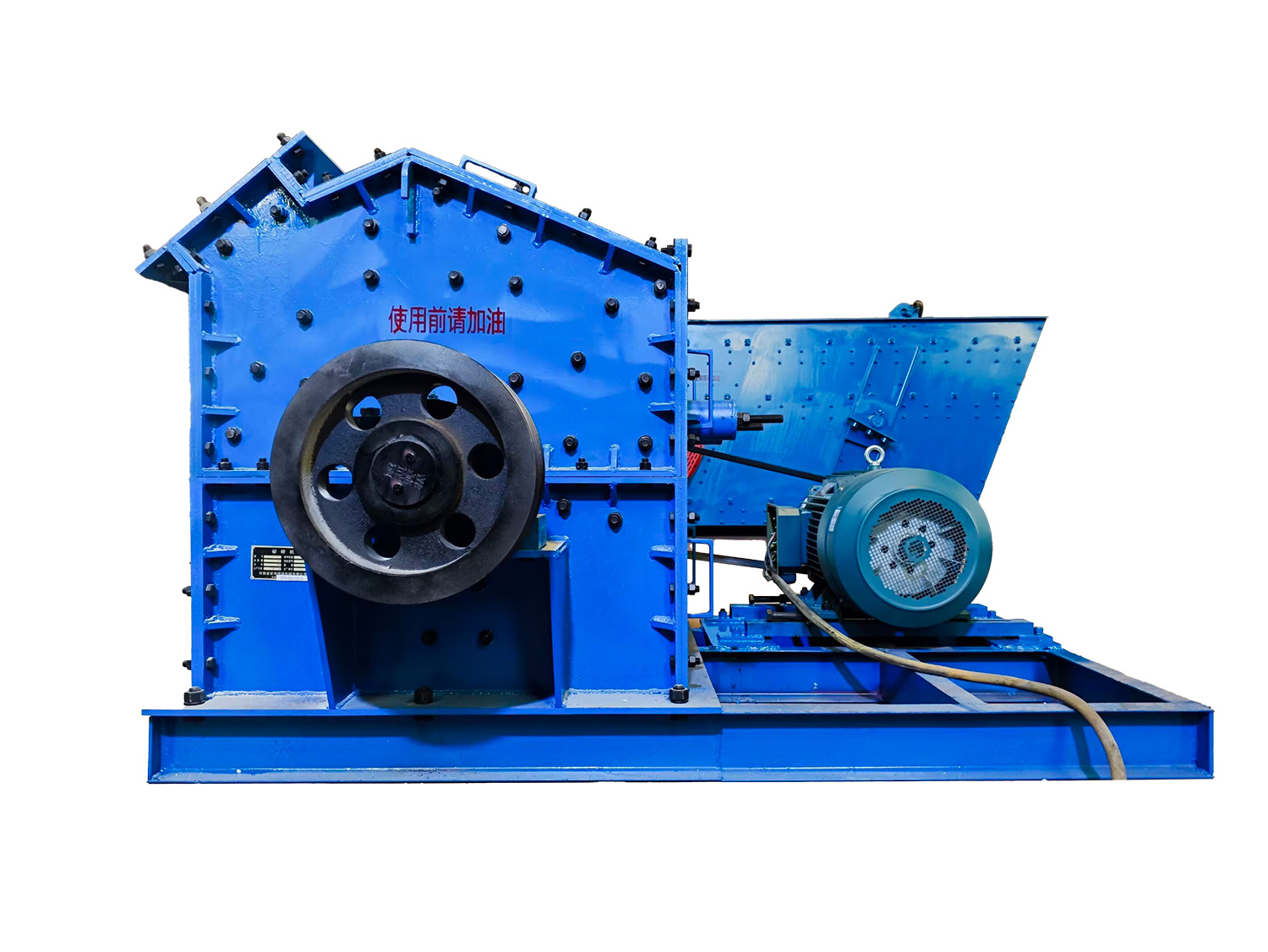

Hammer crushers are industrial machines designed to crush and pulverize materials like coal. They employ a series of hammers that rotate at high speeds, smashing the material against a hard surface. The mechanism allows for various sizes of coal to be processed, making it ideal for the mining industry.

The Mechanics of Hammer Crushers

The core of a hammer crusher consists of a rotor equipped with multiple hammers. When material enters the crushing chamber, it is impacted by the hammers and subsequently reduced in size. The crushed material then exits through a screen, allowing only particles of a certain size to pass. This **mechanical process** is not only efficient but also adaptable to different coal types.

Design Features of Hammer Crushers

Modern hammer crushers come equipped with several design features that enhance their functionality:

- **Heavy-duty construction**: Ensures durability and longevity, capable of withstanding harsh operational conditions.

- **Variable speed control**: Allows for adjustments in rotor speed, offering flexibility in crushing different materials.

- **Robust hammers**: Made from wear-resistant materials, these hammers ensure effective crushing and reduced maintenance costs.

- **Easy access for maintenance**: Designs that allow for quick access to internal components simplify maintenance and reduce downtime.

The Importance of Hammer Crushers in Coal Processing

In coal processing, hammer crushers play a critical role in enhancing operational efficiency. They not only reduce material size but also improve the quality of the final product.

Enhancing Efficiency in Coal Crushing

Efficiency is paramount in coal processing. Hammer crushers ensure a **high throughput** of material, allowing operations to meet production targets without compromising quality. The ability to crush large volumes of coal quickly reduces operational delays, making these machines essential in high-demand settings.

Benefits of Hammer Crushers in Coal Operations

The advantages of utilizing hammer crushers in coal operations include:

- **Cost-Effectiveness**: Reduced energy consumption and lower maintenance costs contribute to overall savings.

- **Versatility**: Suitable for various coal types, from lignite to anthracite, hammer crushers can adapt to different processing needs.

- **Improved Safety**: Modern designs incorporate safety features, minimizing risks associated with coal processing operations.

Operational Challenges and Solutions

While hammer crushers are highly effective, they are not without challenges. Understanding these challenges is crucial for optimizing operations.

Wear and Tear on Components

One of the primary challenges faced is the wear and tear on hammers and screens due to constant impact. Regular maintenance schedules and the use of high-quality materials can mitigate this issue.

Addressing Material Variability

Coal can vary significantly in composition and moisture content. This variability can affect crushing efficiency. Implementing advanced monitoring systems can help operators adjust settings in real-time to accommodate these changes.

Maintenance Best Practices for Hammer Crushers

To ensure longevity and peak performance, hammer crushers require regular maintenance. Implementing best practices can prevent costly downtime.

Routine Inspections

Conducting regular inspections helps identify potential issues before they escalate. Key components to inspect include:

- **Hammers**: Check for signs of wear or damage.

- **Screens**: Look for blockages or tears that could affect efficiency.

- **Bearings and Motors**: Monitor for unusual noises or vibrations.

Proper Lubrication Techniques

Lubrication is vital for reducing friction between moving parts. Adopting a systematic lubrication schedule can extend the life of critical components.

Innovations in Hammer Crusher Technology

As industries evolve, so too do the technologies associated with hammer crushers. Recent innovations are focused on enhancing performance and sustainability.

Automation and Smart Technologies

The integration of automation in hammer crushers allows for real-time monitoring and adjustments. Smart technologies can optimize energy consumption and improve safety by providing data analytics on operational performance.

Sustainable Practices in Coal Crushing

Many manufacturers are focusing on sustainable practices, such as energy-efficient designs and the use of environmentally friendly materials. These initiatives not only benefit the environment but also appeal to a market increasingly concerned with sustainability.

The Future of Hammer Crushers

Looking ahead, the future of hammer crushers seems promising. With ongoing advancements, these machines will continue to evolve, becoming even more efficient and user-friendly.

Market Trends and Predictions

As the global demand for coal remains, the market for hammer crushers is expected to grow. Innovations in design and technology will likely lead to improved performance and reduced operational costs.

Emphasis on Customization

Manufacturers are likely to provide more customizable solutions, allowing operators to tailor machines to specific needs, further enhancing efficiency and productivity.

FAQs About Hammer Crushers

1. What materials can hammer crushers process?

Hammer crushers are versatile and can process various materials, including different types of coal, limestone, and other soft to medium-hard ores.

2. How do I maintain a hammer crusher?

Regular inspections, proper lubrication, and timely replacement of worn-out components are essential for maintaining a hammer crusher.

3. What are the advantages of using a hammer crusher over other types of crushers?

Hammer crushers offer high efficiency, cost-effectiveness, and versatility, making them ideal for coal processing compared to other types of crushers.

4. Can hammer crushers handle wet coal?

While hammer crushers can process wet coal, excessive moisture may lead to clumping. It's crucial to monitor moisture content for optimal performance.

5. What safety features should I look for in a hammer crusher?

Look for machines equipped with automatic shut-off systems, safety guards, and emergency stop buttons to ensure safe operation.

Conclusion

In summary, hammer crushers are undeniably the backbone of modern coal crushing operations. Their efficiency, versatility, and adaptability to various coal types make them essential machinery in the mining industry. As technology continues to advance, the role of hammer crushers will only become more significant, enhancing operational efficiencies while promoting sustainable practices. Proper maintenance, innovative designs, and a focus on safety will ensure that hammer crushers remain at the forefront of coal processing for years to come.

Hot Tags:

PREVIOUS:

Contact Us

E-mail:byunfei2000@gmail.com

Wechat/WhatsApp:+86 17324886663

WhatsApp:+86 18738568071

Address:No. 12 Industrial Road, Zhaipo Town, Xinxiang, Henan Province