Working principle of hammer crusher

Feb 21,2025

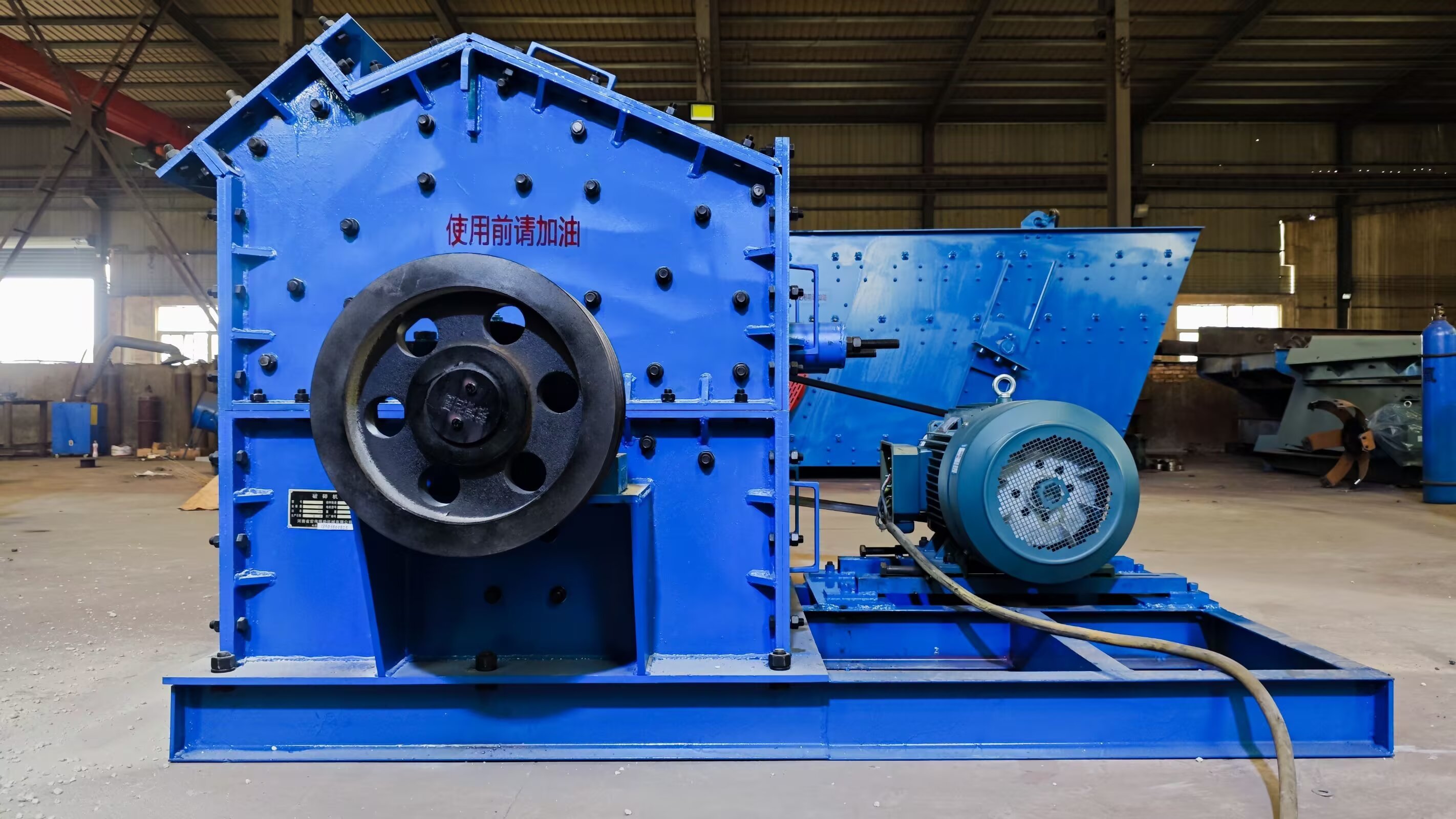

The working principle of a hammer crusher is mainly to achieve material crushing by impacting and shearing the material with a high-speed rotating hammer head. The specific process is as follows:

Feeding: The material is evenly fed into the chamber of the crusher through the feeding equipment.

Crushing: The electric motor drives the rotor to rotate at high speed through a V-belt and a large pulley. The hammer on the rotor strikes the material for the first time, and the material is crushed by the impact of the hammer. The material that gains kinetic energy collides with the counterattack plate at high speed or collides with other materials, further shattering.

Screening and discharging: After multiple crushes in the crushing chamber, materials smaller than the gap between the hammer head and the movable impact plate are released from the crushing chamber under their own weight and the pressure of other materials, and discharged through the feeding hopper. Larger materials continue to be impacted, ground, and squeezed by the hammer until the desired discharge particle size is achieved.

Structural composition

The hammer crusher is mainly composed of the following parts:

Chassis: composed of a lower body, an upper cover, and side walls, with high manganese steel lining embedded in the inner wall.

Rotor: composed of a shaft, hammer head, and bearings, it is the core component of a hammer crusher. It is driven by a motor to rotate, causing the hammer head to generate centrifugal force, thereby achieving material crushing.

Hammer head: The part in direct contact with the material, usually made of high manganese alloy, and its quantity and layout affect the crushing effect of the material.

Counterattack plate: located below the rotor, it is the impact surface when the hammer strikes the material, usually made of wear-resistant alloy.

Screen plate: located at the lower part of the hammer crusher, it plays a role in screening materials. Different specifications of screen plates can be replaced as needed to achieve screening of materials with different particle sizes.

Application Fields

Hammer crushers are suitable for industrial sectors such as cement, chemical, power, and metallurgy. They are mainly used for crushing materials with medium hardness, such as limestone, slag, coke, coal, etc., for intermediate and fine crushing operations.

Hot Tags:

Contact Us

E-mail:byunfei2000@gmail.com

Wechat/WhatsApp:+86 17324886663

WhatsApp:+86 18738568071

Address:No. 12 Industrial Road, Zhaipo Town, Xinxiang, Henan Province